State Whether the Following Instruments Provides a Continuous or Quantized Measurement

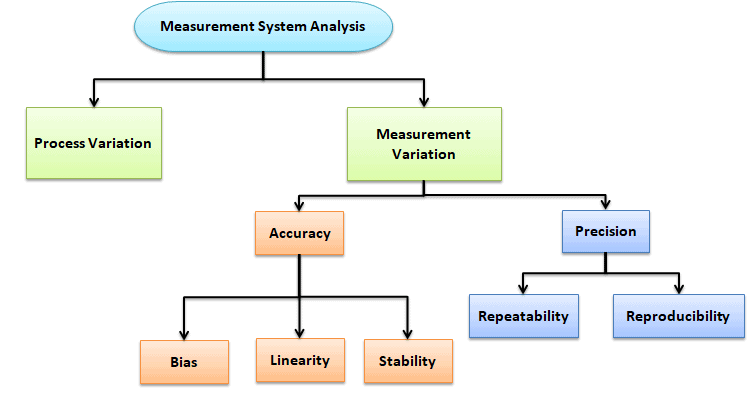

Measurement Systems Analysis (MSA) is a tool for analyzing the variation present in each type of inspection, measurement, and test equipment. It is the system to assess the quality of the measurement system. In other words, it allows us to make sure that the variation in our measurement is minimal compared to the variation in our process.

Measurement is key and essential in six sigma. Measurement System Analysis (MSA) is an experimental and mathematical method of determining how much the variation within the measurement process contributes to overall process variability.

What are Measurement Data and Measurement Variation?

Measurement data is a collection of methods, tools, or gages and operators used to obtain the measurements.

Remember that DMAIC is a tool for removing defects from our process – especially by limiting variation. Moreover, that total observed variation comes in 2 flavors:

Total Variation = Process Variation + Measurement Variation

For example, let's say you measure how many cups of M&Ms are in a production run. If you are measuring using a measuring cup that is not very accurate and your colleague uses an accurate device, you will have different measures. The accumulated variation between your two measuring cups is Measurement Variation.

Alternatively, imagine that a call center has auditors that review the quality of each phone associate's call. If the phone associates are graded on that quality, which impacts their paycheck. So, if every auditor graded to a different standard, there would be a lot of variation in that measurement technique, wouldn't there?

How MSA impacts in DMAIC Phases

- During the measure phase not only do we have to collect data, we have to make sure that we are collecting the same data accurately and consistently.

- Creation of visual tools like Pareto Charts are only as good as the measured DATA.

- In the improve phase you will require precise and accurate data to perform Designs of Experiments and also inform pilot plans.

- In the control phase we use measurements to produce data to perform statistical process control and then prepare things like control charts to visualize if a process is in control or not.

- If our visual factory is based upon data, then that specific control will only be as good as the underlying data.

Why perform Measurement Systems Analysis

The main objective of Measurement system analysis is to gauge the validity of the measuring system and try to minimize the leading to process variation due to the measurement system.

- It gauges the quality of the measurement system or instrument.

- Organizations normally consider measurement data in making decisions regarding the process or business. Hence data should be accurate.

- Data accuracy is one of the fundamental requirements in DMAIC process. It helps to evaluate the effect of the measurement system on the collected data. If the measurement system data is inaccurate, we will make the decision based on incorrect data.

- Monitoring and measuring resources is an important requirement in Quality management systems such as ISO 9001, AS9100 etc.

Fundaments of Accurate Measurement system

Measurement System Analysis aims to qualify a measurement system for use by quantifying its accuracy, precision, and stability.

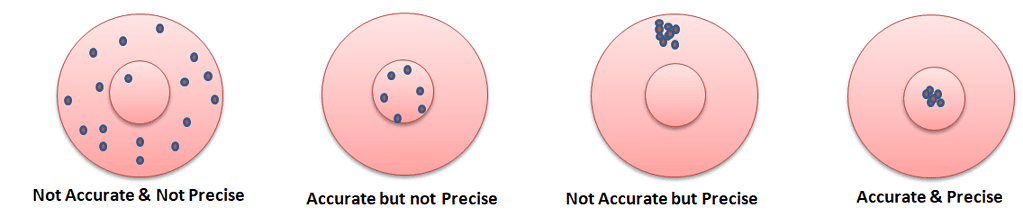

1-Measurement are said to be accurate if their tendency is to center around the actual value of the entity being measured. Measurement accuracy is attained when the measured value has a little deviation from the actual value.

2-Measurement are precise if they differ from one another by a small amount.

Accuracy

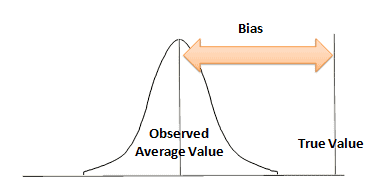

Accuracy is the difference between the true average and the observed average. If the average value differs from the true average, then the system is not accurate. This is an indication of an inaccurate system.

- Bias:Bias is the difference between observed average measurement to the true or reference value. To measure the Bias first needs to measure the same part number of times and then calculate the average of measurement.

Simply Bias = Average of measurement value – Reference or true value.

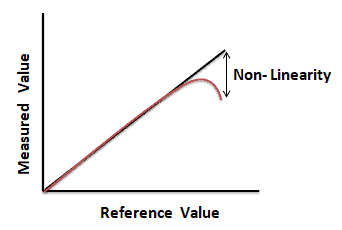

- Linearity:Linearity is the difference in Bias value over the normal operating range of the measuring instrument. In other words, it is the change in Bias over the operating range of the measurement equipment.

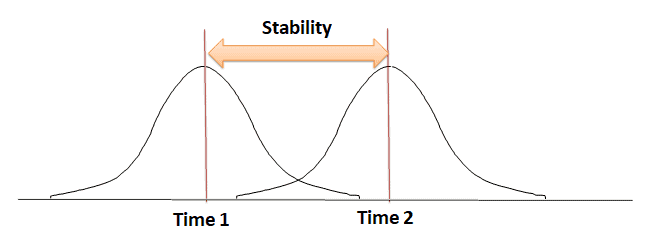

- Stability: Stability refers to the capacity of the measurement system to produce the same values over time when measuring the same sample. In other words, it is the difference in the average of at least 2 sets of measurements with a gage over time. A measurement system is stable, only if there is no special cause of variation affecting the measurement system bias over time.

Precision

The precision of the measurement system is the degree to which repeated measurement under unchanged conditions show the same result. In other words, precision refers to the closeness of two or more measurements to each other.

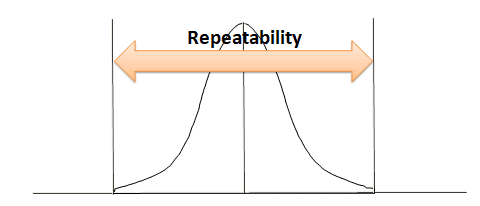

- Repeatability: Repeatability is the variation between successive measurements of the same part, same characteristic, by the same person using the same gage. In other words, how much variation do we see in measurements taken by the same person, on the same part, using the same tool?

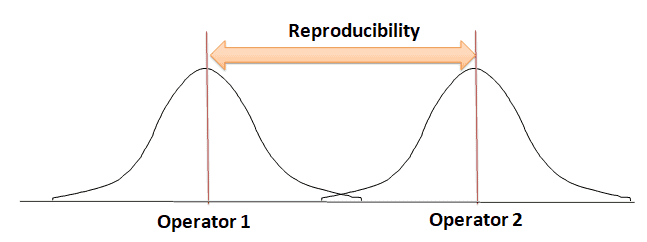

- Reproducibility:Reproducibility is the difference in the average of the measurements by different people using the same instrument when measuring the identical characteristic on the same part. In other words, how much variation do we see in measurements taken bydifferent people on the same part, using the same tool?

Also see Gage Repeatability and Reproducability

Calibration

Calibration is the process of comparing a measurement standard or an instrument with a known accuracy to another standard or instrument. We do this to detect or correlate any variation to perform adjustments to eliminate measurement error.

Calibration Interval

Must be based on stability, purpose, and degree of use.

Principles of Calibration

- Stability of measurement instrument

- Purpose of the measurement instrument

- How the environment interacts with the measurement instrument

Calibration Standards

Calibration is a comparison of instrument performance to standards of known accuracy; A standard is a physical representation of a unit of measurement. In other words, a known accurate measure of a physical quantity.

When a measurement of characteristics is made, the dimension being measured is compared to a standard. It may be a yardstick and represents some conditions against which an object is compared obviously to a national or international standard.

Types of standard measurements are:

- In-house calibration lab or working level: Labs are set up within the organization itself for calibration of gages or instruments.

- Calibration standards: Labs are set up by professionals to calibrate the working level standards. Labs will generally be sent to the national standard laboratories on a periodic basis to calibrate their instruments.

- National standards: National standard laboratories are maintained by different parts of the world. These are absolute standards of high accuracy that can be used as ultimate reference standards. They provide certification to laboratories that maintain entire norms as per national standards.

- International standards: Maintained by "international Bureau of Weight and Measure" and are not available for ordinary users for the purpose of comparison or calibration.

The ultimate goal of industries is to provide quality products to customers. The aim of the product is not only to fulfill the user's requirement but also to have a specified dimension. Measurement of dimension is not always perfect and reliable unless measuring instruments are calibrated accurately. Thus, calibration plays a vital role in maintaining Quality.

Measurement Error

In Six Sigma, we want to base as much of our decisions on reliable data as possible. Measurement System Analysis uses techniques to understand the variation within measuring equipment.

For example, it is the variation brought into the equipment by people and by the environment. There are some useful methods for estimating how much error due to gage and also by an individual.

Measurement Error is considered to be the difference between a value measured and the true value. It depends upon two things.

- What kind of instrument that you are using

- Who is the person using an instrument

Therefore, anytime you are using an instrument, keep your mind open about measurement error possibilities.

How Much Measurement Error is Acceptable?

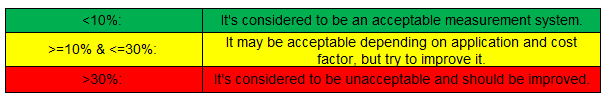

According to AIAG (2002), a general rule of thumb for measurement system acceptability is:

- Under 10 percent error is satisfactory.

- 10 percent to 30 percent error suggests that the system is acceptable. Also, it depends on the importance of the application, cost of the measurement device, cost of repair, and other factors.

- Consider over 30 percent error is unacceptable. Hence you should improve the measurement system.

The procedure of Measurement Systems Analysis (from here)

- Determine the type of data collection. Identify whether the data is continuous or discrete.

- Determine the number of appraisers, number of sample parts, and also the number of repeat readings.

- Larger numbers of parts and repeat readings give results with a higher confidence level. But also consider the time, cost, and disruption.

- Use appraisers who normally perform the measurement and who are familiar with the equipment and procedures.

- In particular, make sure there all the appraisers follow measurement procedures.

- Select the sample parts to represent the entire process spread. This is a very critical point.

- If applicable, mark the exact measurement location on each part to minimize the impact of within-part variation (e.g. out-of-round).

- Furthermore, ensure that the measurement device has adequate discrimination/resolution, as discussed in the Requirements section.

- Parts should be numbered, and the measurements should be taken in random order so that the appraisers do not know the number assigned to each part or any previous measurement value for that part. Also, a third party should record the measurements, the appraiser, the trial number, and the number for each part on a table.

Also, refer Gage R&R for Gage Repeatability and Reproducibility calculations for both Average & Range and ANOVA method

Measurement Systems Analysis Videos

Six Sigma Green Belt Certification Measurement Systems Analysis Questions:

Question: As we calibrate our Measurement System to assure accurate data we frequently encounter Bias which is the __________________ of a measured value from the ________________ value. (Taken from Iassc sample Green Belt exam.)

(A) Spread, Mean of the population

(B) Deviation, hoped for

(C) Deviation, true

(D) Spread, idea

Answer:

Six Sigma Black Belt Certification Measurement System Analysis Questions:

Question: In measurement system analysis, which of the following pairs of data measures is used to determine total variance? (Taken from ASQ sample Black Belt exam.)

(A) Process variance and reproducibility

(B) Noise system and repeatability

(C) Measurement variance and process variance

(D) System variance and bias

Answer:

Question: A measurement system analysis is designed to assess the statistical properties of:

(A) gage variation

(B) process performance

(C) process stability

(D) engineering tolerances

Answer:

clendinnenviberand.blogspot.com

Source: https://sixsigmastudyguide.com/measurement-systems-analysis/

0 Response to "State Whether the Following Instruments Provides a Continuous or Quantized Measurement"

Post a Comment